The Industrial Revolution of Synthetic Diamonds: Unlocking Transformative Applications Across Key Sectors

Applications for synthetic diamonds in modern industrial advancement

Synthetic diamonds, once primarily considered a laboratory curiosity or a less expensive alternative to natural gemstones, have emerged as a cornerstone material in modern industrial advancement. These engineered materials, chemically and physically identical to their geological counterparts, are fundamentally reshaping diverse sectors due to their unparalleled combination of properties, including extreme hardness, superior thermal conductivity, and unique electrical insulating and semiconducting capabilities.1 A significant development in this field is the ability to precisely control their production, allowing for the tailored engineering of specific characteristics that natural diamonds, with their inherent variability, cannot consistently provide.3 This capability represents a profound shift: synthetic diamonds are not merely substitutes but purpose-built advanced materials, meticulously designed to meet the exacting demands of high-performance industrial applications. This tailored material engineering unlocks a vast array of possibilities where consistency, purity, and specific property optimization are paramount, driving innovation across various sectors.

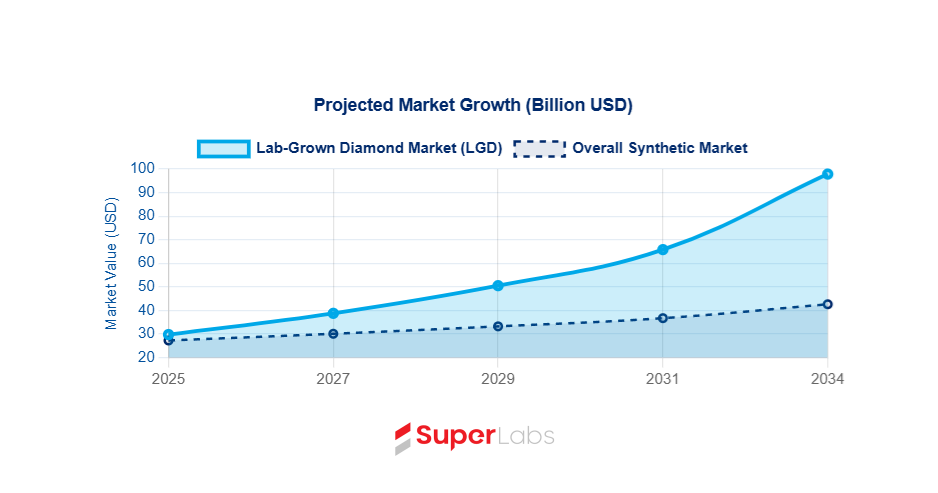

The industrial applications of synthetic diamonds currently represent the largest segment of the market, with cutting tools and abrasives holding a substantial 39% market share in 2024 and projected for continued growth through 2034.5 Beyond these traditional uses, a rapid expansion is evident in high-tech domains such as electronics, medical devices, optics, and aerospace. These combined industries in the United States alone are anticipated to grow at an impressive average annual rate of 15%.5 This diversification signifies a crucial maturation of the synthetic diamond market. It is moving beyond a high-volume, lower-margin material for conventional abrasives to become a critical, high-value component in advanced technological fields. This suggests a future where synthetic diamonds are foundational to next-generation electronics, quantum systems, and medical devices, driven by performance-critical needs rather than just bulk material replacement. The global synthetic diamond market was valued at an estimated USD 25.9 billion in 2024 and is projected to achieve a Compound Annual Growth Rate (CAGR) of 5.1% from 2025 to 2034.5 This report delves into the intrinsic properties, manufacturing methodologies, and the expansive, transformative industrial applications of synthetic diamonds, concluding with an analysis of market dynamics and future trajectories.

1. Introduction to Synthetic Diamonds

1.1 Defining Synthetic Diamonds: Identity, Properties, and Industrial Relevance

Synthetic diamonds, often referred to as lab-grown or cultured diamonds, represent a remarkable triumph of material science. They are meticulously manufactured through sophisticated technological processes that precisely replicate the extreme conditions under which natural diamonds form deep within the Earth's mantle.6 Fundamentally, these engineered diamonds are chemically identical to their natural counterparts, comprising pure carbon atoms arranged in an identical crystalline structure.1 This shared atomic arrangement is responsible for their identical physical and optical properties, including the characteristic fire, scintillation, and sparkle that make diamonds highly prized.9

While visually indistinguishable to the unaided eye, skilled gemologists employ specialized tools and techniques to differentiate between natural and synthetic diamonds. One key identifier lies in the presence of trace elements: natural diamonds typically contain minute amounts of nitrogen, whereas lab-grown diamonds often exhibit no nitrogen, a distinguishing feature for gemological analysis.9 Furthermore, the controlled environment of laboratory synthesis often results in characteristic growth patterns visible under magnification, which contrast with the unique inclusions or blemishes found in natural diamonds, often likened to nature's distinct fingerprints.10 Differences in their reaction to ultraviolet (UV) light can also serve as a diagnostic tool; synthetic diamonds may display a more uniform fluorescence, sometimes appearing in orange or green hues, depending on their specific manufacturing process.12 To ensure authenticity and traceability, many certified synthetic diamonds are laser-inscribed on their girdle, an inscription invisible to the naked eye that indicates their synthetic origin.12

For industrial applications, a critical aspect of synthetic diamonds is their capacity for precise property engineering. This controlled synthesis frequently yields materials with superior hardness, higher thermal conductivity, and greater consistency in quality when compared to many naturally formed diamonds.3 The laboratory environment minimizes the incorporation of impurities and defects, leading to a higher degree of purity and fewer internal flaws.10 This heightened purity and structural integrity are paramount for high-performance industrial components, where even microscopic imperfections can compromise functionality or longevity. The ability to control these attributes represents a progression from simply imitating nature to actively mastering material synthesis. This subtle yet profound shift means that synthetic diamonds are not merely a cheaper or more ethical substitute; they are a distinct class of advanced materials. Their ability to be tailored for specific industrial demands, such as producing defect-free crystals for semiconductor applications or diamonds with optimized thermal conductivity for heat sinks, renders them indispensable in situations where natural diamond's inherent variability and impurities would be detrimental. This mastery over synthesis is the core enabler for their transformative impact across a multitude of high-tech industries.

1.2 Manufacturing Processes for Industrial-Grade Diamonds: HPHT and CVD

The production of industrial-grade synthetic diamonds primarily relies on two sophisticated methodologies: High Pressure, High Temperature (HPHT) and Chemical Vapor Deposition (CVD). Each method offers distinct advantages and is suited for different applications, though both are continually refined to enhance output quality and efficiency.

High Pressure, High Temperature (HPHT)

The HPHT method directly replicates the geological conditions deep within the Earth where natural diamonds are formed over millennia. This process subjects a carbon source to extremely high temperatures, typically ranging from 1400°C to 2000°C, and immense pressures, often exceeding 1.5 million PSI or 5-6 Gigapascals (GPa).2 The synthesis begins with a small diamond seed crystal, a high-purity carbon source (such as graphite), and a molten metal catalyst (e.g., iron, nickel, or cobalt).6 Under these conditions, the molten metal dissolves the carbon, which then precipitates and crystallizes onto the diamond seed, growing layer by layer. The substance is then carefully cooled to form the rough diamond.18

Historically, HPHT was the pioneering method for producing lab-grown diamonds, with General Electric successfully synthesizing them in 1954.8 It was traditionally, and remains, a widely employed technique for manufacturing industrial diamonds, particularly for producing rough diamonds used in abrasive applications.21 HPHT diamonds typically exhibit a cuboctahedron shape and demonstrate growth in 14 distinct directions.20 Beyond new diamond creation, the HPHT process can also be applied to natural diamonds to permanently enhance their color, improving their aesthetic grade to more desirable ranges.18

Chemical Vapor Deposition (CVD)

CVD represents a more contemporary advancement in synthetic diamond manufacturing, conceptually drawing inspiration from the formation of diamonds in interstellar gas clouds.17 This process involves placing a diamond seed or a graphite source into a vacuum chamber, which is then meticulously evacuated to a high vacuum to prevent contamination.17 The chamber is subsequently filled with carbon-rich gases, predominantly methane, often mixed with hydrogen or oxygen.6 Energy, typically supplied by heat (e.g., thermal filaments) or ionized plasma (e.g., microwaves or lasers), is then introduced to break down the chemical bonds of these gases.6 This allows individual carbon atoms to precisely deposit layer by layer onto the seed, forming the diamond crystal.17

A significant operational advantage of CVD is its ability to function at considerably lower temperatures and pressures (typically under 27 kPa) compared to the HPHT method, which simplifies the overall manufacturing process and reduces energy requirements.17

The advantages of CVD for industrial applications are particularly compelling:

- Chemical Purity: CVD processes are capable of yielding diamonds of exceptional chemical purity, often free from the metallic or nitrogen inclusions that can sometimes be present in HPHT diamonds due to the use of catalysts and gases like nitrogen and boron.17 The precise control over gas composition during CVD allows for the deliberate reduction of impurities, leading to a purer final product.19

- Substrate Deposition: A unique and highly valuable capability of CVD is its ability to deposit diamond films and coatings on various substrates other than diamond itself.17 This is critical for creating integrated diamond components and surface enhancements across diverse materials, which has led to significant technological advancements in optics, computer sciences, and tool production.17

- Flexibility and Control: The CVD method offers superior flexibility in controlling the size, shape, and even specific crystallographic orientation of the diamonds produced.19 This enhanced control over chemical impurities allows for precise manipulation and tailoring of the resulting diamond properties to meet the exact specifications required for specialized applications.19

- Large Area Growth: CVD technology facilitates the growth of diamonds over extensive surface areas, making it highly suitable for industrial-scale production of diamond films, coatings, and wafers, which are crucial for electronics and optical components.19

- Growth Morphology: In contrast to HPHT diamonds, CVD diamonds typically grow in a cubic shape with a single primary growth direction, which can be advantageous for certain applications requiring specific crystal orientations.20

Historically, one limitation of CVD was its inability to consistently yield diamonds over 3.2 carats, a factor primarily relevant to the jewelry industry.17 However, continuous technological advancements are steadily improving the size capabilities of CVD-grown diamonds, further expanding their industrial utility.4

Comparison and Evolution

While HPHT was the pioneering method and remains indispensable for certain industrial applications, particularly for bulk rough diamond production, CVD has increasingly become the preferred approach for many high-tech uses. This preference stems from CVD's lower operating conditions, its superior control over purity, and its unique ability to deposit diamond films on diverse substrates.17 The flexibility of CVD in substrate deposition directly enables the creation of diamond coatings and integrated diamond components, which are essential for advanced electronics, optics, and semiconductor applications. The precise control over impurities allows for the fine-tuning of electrical, thermal, and optical properties, making CVD a key enabling technology for the next generation of high-performance industrial diamond applications. This signifies that CVD is not merely an alternative manufacturing method but a fundamental driver of innovation in these high-tech sectors. Both HPHT and CVD methods are subject to ongoing research and development, continually pushing the boundaries of synthetic diamond production capabilities.22

Table 1: Comparison of HPHT vs. CVD Synthesis Methods for Industrial Applications

1.3 Fundamental Properties Driving Industrial Adoption

The widespread and growing adoption of synthetic diamonds across diverse industrial sectors is fundamentally driven by their extraordinary combination of physical, chemical, and electrical properties. These attributes collectively position diamond as a "supermaterial," capable of delivering extreme performance in applications where conventional materials fall short.1

Exceptional Hardness and Wear Resistance

Diamond is universally acknowledged as the hardest known material, registering a perfect 10 on the Mohs scale.2 Its Knoop hardness is approximately 9000 kg/mm², which is remarkably higher than other hard materials such as boron nitride (4500 kg/mm²) or tungsten carbide (2190 kg/mm²).2 This unparalleled hardness stems from its robust covalent bonds and the dense tetrahedral arrangement of carbon atoms within its crystal lattice.1 This property makes synthetic diamond the ideal material for cutting, drilling, grinding, and polishing tools across heavy industries. Its application in these tools translates directly into extended tool lifetimes, minimized wear, significant reductions in downtime, and overall lower operating costs, thereby enhancing efficiency and profitability across various industrial processes.1 Furthermore, synthetic diamonds can be precisely manufactured to possess an ultra-fine edge, enabling exceptionally high precision in demanding machining and tooling applications.23

Outstanding Thermal Conductivity

Synthetic diamond boasts the highest thermal conductivity among all known materials. At room temperature, its thermal conductivity can reach an impressive 2000-2200 W/mK, which is five times greater than copper and ten times superior to aluminum nitride.1 Some isotopically pure monocrystalline synthetic crystals can even achieve an astonishing 3320 W/mK.27 This exceptional thermal property is critical for thermal management applications, particularly in the electronics sector, where synthetic diamonds are extensively employed as highly efficient heat sinks. They play a vital role in preventing overheating in high-power electronic devices such as central processing units (CPUs), laser diodes, transistors, and various integrated circuits, thereby ensuring optimal performance, extending operating life, and enhancing overall durability.1 In abrasive applications, diamond's thermal conductivity also serves a crucial function by efficiently drawing heat away from the grinding zone, which minimizes thermal damage to the workpiece and helps maintain its material integrity during high-speed operations.26

Unique Electrical Properties

In its pure, undoped form, diamond is an excellent electrical insulator, exhibiting very high electrical resistivity (greater than 10^14 Ω·m) and a wide electronic band gap of approximately 5.45 eV.1 This intrinsic characteristic allows it to withstand extremely high voltages without experiencing electrical breakdown, making it ideal for insulating high-power electronic components.31 However, diamond's electrical properties can be precisely modified through controlled doping. For instance, doping with boron can create a p-type semiconductor, while phosphorus doping can create an n-type semiconductor.2 This capability enables the development of advanced electronic components such as high-power switches in power stations, high-frequency field-effect transistors, and light-emitting diodes.1 Compared to conventional semiconductors like silicon, diamond offers superior carrier mobility and a significantly higher breakdown electric field.1 A hydrogen-terminated diamond surface can also form a p-type hole conductive layer, further expanding its utility in semiconductor devices.33

Broad Optical Transparency

Diamond exhibits transparency across an exceptionally wide spectral band, extending from the deep ultraviolet (220 nm) through the entire visible spectrum to the far infrared and millimeter-wave microwave regions (exceeding 50 µm).23 Its naturally low absorption of light, coupled with its remarkable ability to rapidly dissipate any absorbed energy, makes it an ideal material for optical components such as lenses, windows, and laser optics.1 This is particularly crucial in high-power laser systems, where thermal distortion caused by absorbed energy must be meticulously avoided to maintain beam quality and system performance.36

Chemical and Biological Inertness

Synthetic diamonds are inherently chemically and biologically inert, meaning they are non-reactive and exhibit exceptional stability even in the most aggressive chemical, physical, and radioactive environments.23 This robust chemical stability prevents degradation and ensures long-term performance in corrosive or harsh industrial settings. Furthermore, their biocompatibility is a key factor enabling their use in various medical applications, ensuring safety and seamless compatibility with biological systems without eliciting adverse reactions.4

Acoustic Properties

Synthetic diamonds also possess excellent acoustic properties, which are leveraged in specialized applications. For instance, CVD diamond tweeters are utilized in high-end audio systems, contributing to the reproduction of high-frequency sounds with unmatched clarity and transparency.23

The true value of synthetic diamonds in industrial applications lies not just in each individual property, but in the unique synergy of these multiple extreme properties within a single material. This combination allows synthetic diamonds to address complex, multi-faceted engineering challenges that no other single material can comprehensively solve. For example, in quantum technologies, the robust structure, exceptional heat conductivity, and lack of electrical conductivity are all simultaneously crucial for insulating qubits.1 This integrated performance is critical for enabling breakthroughs in miniaturization, efficiency, durability, and overall system performance across diverse high-tech sectors, making synthetic diamond a foundational material for future technological advancements.

Table 2: Key Properties of Synthetic Diamonds and Their Industrial Relevance

2. Core Industrial Applications: Abrasives and Tools

Synthetic diamonds are preeminent materials in the abrasives and tooling sector, a domain where their exceptional hardness and wear resistance are exploited to their fullest potential. This segment continues to represent the largest application area for synthetic diamonds, underscoring their indispensable role in heavy industries worldwide.5

2.1 Precision Cutting and Drilling Tools

Synthetic diamond tools are extensively utilized in some of the most demanding industrial environments, including large-scale construction projects, mining operations, oil and gas exploration, and precision machining across various manufacturing sectors.1 Their ability to withstand extreme conditions and maintain cutting efficiency under immense stress makes them superior to conventional materials.

These tools are specifically engineered to incorporate synthetic diamonds into critical components, such as diamond-tipped drill bits and saws.3 Polycrystalline diamond (PCD) cutting tools, which are fabricated by sintering diamond particles with a metallic binder under high pressure and temperature, are particularly effective for machining extremely hard metals like titanium and tungsten carbide.3 Diamond blades are indispensable for the precision cutting of challenging materials such as glass, advanced ceramics, and semiconductor wafers, where a clean, precise cut is paramount to avoid material damage.3 They are also increasingly employed for the precision cutting of gemstones, ensuring high-quality finishes.3 Furthermore, diamond-coated cutting tools demonstrate remarkable efficacy in cutting through robust construction materials like concrete, granite, and marble, materials that would rapidly dull or destroy conventional tools.3

The performance advantages derived from using synthetic diamond tools are substantial. They translate directly into an extended tool lifespan, significantly enhanced operational performance, substantial reductions in machine downtime, and overall lower operating costs for industrial processes.1 For instance, Polycrystalline Diamond Compact (PDC) bits, widely used in drilling operations, offer a higher rate of penetration (ROP), a considerably longer lifespan, improved overall drilling efficiency, and superior steerability, which is crucial for directional drilling applications.39 Diamond saws and drills are engineered to deliver high-quality, cleaner cuts with less heat generation and reduced debris. This not only preserves the structural integrity of the material being cut but also contributes to a quieter and safer working environment by reducing noise and airborne particulates.40

In the critical sectors of oil and gas drilling, PCDs are indispensable components due to their unparalleled ability to withstand the extreme conditions encountered deep underground, providing substantial economic benefits to rig drilling operators through increased efficiency and reduced operational delays.23 Similarly, diamond core drills are routinely employed in geological surveys and rock core sampling, enabling precise and efficient material extraction for analysis and resource assessment.3 Within the construction industry, synthetic diamond-tipped core drills have become essential tools for major infrastructure projects, such as bridge and tunnel construction, allowing for efficient boring through dense materials like concrete, marble, and reinforced structures.3

2.2 Advanced Grinding and Polishing Applications

Synthetic diamonds also play a pivotal role in precision grinding and polishing processes, which are critical for achieving exacting tolerances and surface finishes across diverse industries, including automotive, aerospace, electronics, and tool-making.3

Synthetic diamond grinding wheels are widely employed to polish metals, sharpen carbide tools, and efficiently process extremely tough materials like tungsten carbide and advanced ceramics, which are commonly used in high-performance components.3 For applications requiring microscopic accuracy, such as the finishing of sensitive materials like semiconductors and optical lenses, nano-diamond abrasives are specifically utilized for ultra-precision polishing.3

Diamond polishing compounds, often formulated as pastes comprised of micron-sized synthetic diamonds, are indispensable for lapping, polishing, and finishing a wide range of materials. These include semiconductors, molds, dies, metallurgical samples, metalwork, hard disk drives, wire dies, and ceramics.42 These compounds ensure a consistent, high-quality, smooth, and defect-free surface finish, which is vital for precision engineering, particularly in industries where surface integrity directly impacts performance.42 These pastes are available in various formulations, such as water-soluble and oil-soluble, to meet specific cleaning and lapping requirements, offering flexibility for different industrial processes.43

The versatility of synthetic diamonds in grinding is further reflected in the diverse types of grinding wheels available, each tailored for specific applications:

- Resin bond diamond wheels are popular for their versatility and balance of performance and cost. They are ideal for fine finishing applications due to their smooth grinding action, often used for carbide tools and polishing glass and ceramics.41

- Metal bond diamond wheels are renowned for their durability and long lifespan, making them well-suited for rough grinding applications where high abrasion resistance is crucial, such as grinding glass, ceramics, and concrete.41

- Vitrified bond diamond wheels offer excellent rigidity and thermal stability. These wheels are ideal for precision grinding applications where paramount dimensional accuracy is required, such as cylindrical grinding of automotive and aerospace components.41

- Electroplated diamond wheels feature a single layer of diamond particles bonded by a nickel matrix, providing a very sharp, aggressive grinding action. They excel in specialized applications demanding high precision and fine surface finishes, including intricate profile grinding and detailed contouring in craft and jewelry-making.41

2.3 Advantages of Synthetic Diamonds in Abrasive Applications

The widespread adoption of synthetic diamonds in abrasive applications is driven by a compelling array of advantages that significantly outperform traditional materials.

Synthetic diamond tools offer superior performance metrics, including high cutting efficiency, optimal hardness, enhanced accuracy, exceptional durability, and overall cost-effectiveness compared to conventional abrasive materials.3 This translates directly into improved productivity and reduced operational overhead for industries.

A significant, yet often understated, advantage of lab-created diamonds is their unmatched composition quality and consistency. Unlike natural diamonds, whose formation in geological processes results in inherent variability and imperfections, synthetic diamonds are grown under tightly controlled laboratory conditions.15 This meticulous control minimizes the imperfections commonly found in natural stones, effectively eliminating the need for extensive quality ratings and leading to a more consistent production output.15 In industrial settings, particularly those requiring high precision and automation, consistency is as critical as raw material properties. Predictable material behavior reduces variability in manufacturing processes, minimizes defects, streamlines quality control, and enables higher yields. This translates into significant cost savings, improved efficiency, and enhanced reliability of final products. Therefore, the controlled, consistent nature of synthetic diamonds is a powerful, often understated, driver of their adoption in advanced manufacturing, moving beyond simple performance metrics to address systemic production efficiencies.

Furthermore, synthetic diamonds can be produced in a wide variety of close-tolerance shapes and sizes, providing greater design flexibility for tool manufacturers than what is possible with the naturally occurring, often irregular forms of mined diamonds.15 This customization allows for the creation of highly specialized tools optimized for specific tasks.

Synthetic diamond abrasive logs are typically larger and exhibit significantly longer wear life on grinding wheels, which directly reduces the frequency of tool changes and minimizes machine downtime.15 This extended longevity contributes substantially to continuous operation and higher throughput.

Their excellent thermal conductivity ensures that heat generated during high-speed cutting, drilling, or grinding operations is rapidly dissipated away from the contact zone. This efficient heat management reduces thermal damage to the workpiece, helps maintain its material integrity, and prevents premature tool degradation.26

Collectively, the extended tool life, enhanced performance, and superior material characteristics directly translate into lower overall tooling costs and reduced machine downtime. This significantly improves operational efficiency and profitability across a wide range of industrial applications, solidifying synthetic diamonds' position as the material of choice for demanding abrasive and tooling needs.1

3. Advanced Industrial Applications: Electronics and Thermal Management

The electronics sector represents one of the most dynamic and promising areas for the application of synthetic diamonds. Their unique combination of properties, particularly their unparalleled thermal conductivity and exceptional electrical characteristics, makes them exceptionally well-suited for next-generation semiconductors and advanced thermal control solutions.5 The escalating demand for artificial diamonds in this industry is intrinsically linked to the rapid advancements in fields such as Artificial Intelligence (AI), Quantum Computing, the Internet of Things (IoT), and Autonomous Vehicles, all of which require increasingly powerful and reliable electronic components.5

3.1 High-Performance Heat Sinks and Thermal Spreaders

The relentless pursuit of miniaturization and increased performance in electronic devices has made heat accumulation a major limiting factor and a significant design challenge. Approximately 50% of all electronic device failures are directly attributed to heat-related issues.1 As more power is packed into smaller footprints, the efficient dissipation of this generated heat becomes paramount for device longevity and optimal operation.27

Synthetic diamonds, with their unparalleled thermal conductivity (reaching up to 2000-2200 W/mK at room temperature), are employed as ideal heat sinks and thermal spreaders to address this critical challenge.1 They efficiently dissipate heat from high-power electronic devices, including central processing units (CPUs) in advanced computers, laser diodes, transistors, and various integrated circuits. This active thermal management ensures optimal performance, extends the operating life of components, and enhances overall system durability by preventing thermal degradation.1

The quantifiable impact of integrating synthetic diamonds into thermal management solutions is substantial. For example, replacing traditional ceramic substrates with metalized diamond heat spreaders in high-voltage insulated-gate bipolar transistors (IGBTs) can more than halve the junction-to-case thermal resistance, effectively doubling the IGBT's power rating.1 This leads to significantly lower operating temperatures and allows for increased power output in critical components like RF amplifiers and microwave/millimeter-wave circuits.24 Element Six's Diafilm™ TM220, a leading diamond thermal solution, offers thermal conductivity exceeding 2200 W/mK, demonstrating its capability to lower junction temperatures by up to 40°C and increase device efficiencies by 10% or more.28

This "supermaterial" 1 holds immense value across a broad spectrum of electronic and electrical applications. This includes telecommunications equipment, where heat accumulation can jeopardize circuitry integrity and performance, and microelectronic devices.1 Furthermore, synthetic diamonds are crucial in high-voltage IGBT applications found in electric vehicles, train systems, aerospace power generators, and alternative energy distribution systems, where efficient power conversion and heat management are essential.1 In high-power laser systems, synthetic diamonds are critical for effectively dissipating heat and preventing damage to sensitive optical components.24

3.2 Next-Generation Semiconductor Components and Devices

As traditional semiconductor materials like silicon (Si) rapidly approach their fundamental physical limits in terms of performance and miniaturization, synthetic diamond is emerging as a groundbreaking, next-generation ultra-wide bandgap semiconductor material.1 Its inherent properties offer a significant leap forward in power electronics and high-frequency applications.

Diamond possesses a band gap of approximately 5.45 eV, which is five times wider than that of silicon (1.1 eV).1 This wider band gap directly translates to a 30-fold higher breakdown electric field (4500 V/cm for diamond compared to 1500 V/cm for silicon), which in turn allows for significantly higher output bias voltages and, consequently, increased available power in devices.1 Furthermore, diamond's electron mobility is three times greater than silicon, leading to reduced on-state resistance and lower power consumption during operation.1 Theoretically, diamond-based semiconductors are said to be capable of controlling 50,000 times the power of mainstream silicon, highlighting their immense potential for high-power applications.32

While pure diamond is an excellent electrical insulator, its electrical properties can be precisely tailored through controlled doping. Introducing elements like boron can create a p-type semiconductor, while phosphorus doping can yield an n-type semiconductor.24 Additionally, a hydrogen termination on the diamond surface can form a p-type hole conductive layer, offering another pathway for creating active semiconductor regions.33 This ability to engineer specific conductivity types allows for the fabrication of complex semiconductor devices.

These exceptional properties make synthetic diamond semiconductors ideal for a range of high-impact applications. They are critical components in high-power electronics, including essential systems in electric vehicles (EVs), where they can improve energy efficiency and extend driving range.31 They are also vital for renewable energy systems, enabling more efficient power conversion and management, and for advanced 5G networks, where their high electron mobility allows for high-frequency transistors and faster data transfer.31 Diamond transistors exhibit high radio-frequency (RF) power capability, comparable to or even exceeding that of gallium arsenide (GaAs) transistors, making them suitable for radar and communication systems.1

The adoption of diamond semiconductors promises transformative benefits for various industries. These include improved energy conversion efficiency, potentially reaching up to 99%.34 For electric vehicles, this could mean an increased autonomy of nearly 10% without requiring larger batteries.34 Furthermore, the production and use of diamond semiconductors are estimated to result in a significant reduction in CO2 levels compared to silicon carbide (SiC) and silicon, contributing to environmental sustainability.34 Ultimately, this technology enables the development of electronic devices that are not only smaller and more powerful but also substantially more energy-efficient, driving innovation across sectors from automotive to telecommunications.32

4. Emerging and Specialized Industrial Applications

Beyond their established roles in abrasives and advanced electronics, synthetic diamonds are rapidly expanding their footprint into a diverse array of specialized and emerging industrial applications, leveraging their unique combination of extreme properties to enable breakthroughs in various high-tech fields.

4.1 Quantum Sensing and Computing

Synthetic diamonds are at the forefront of innovation in quantum technologies, opening new frontiers in quantum sensing and computing.1 This transformative potential is primarily attributed to the presence of Nitrogen-Vacancy (NV) centers within the diamond lattice. These atomic-scale defects, formed when a nitrogen atom replaces a carbon atom adjacent to a vacant lattice site, exhibit remarkable quantum behavior even at room temperature.1

The diamond's robust crystal structure provides an exceptionally stable environment for these NV centers, effectively insulating the qubit (quantum bit) from its external environment due to its robust structure, exceptional heat conductivity, and inherent lack of electrical conductivity.1 This stability is crucial for maintaining quantum coherence for extended periods, with electron spin qubits maintaining coherence for milliseconds and nuclear spin qubits for over a second, far surpassing the coherence times of superconducting qubits.45

These unique quantum capabilities enable the development of highly sensitive sensors for a variety of applications, including high-resolution magnetometry, which can be used in medical imaging (e.g., MRI) and geological exploration.1 In quantum computing, NV centers serve as stable qubits that can be manipulated and read using magnetic fields and microwave radiation.35 The ability of diamond spin qubits to connect with other quantum modules using light allows for flexible and interconnected computations, offering advantages in scalability compared to other quantum computing architectures.45 Researchers are also exploring the use of tin-vacancy (SnV) centers, which exhibit higher emission efficiency and are less affected by external electric fields, leading to more integrated quantum chips.45 Furthermore, quantum diamonds are being developed for nanoscale imaging and bio-labeling, and quantum-enhanced metrology, pushing the boundaries of precision measurement.44

4.2 Optical Components and High-Power Lasers

Synthetic diamond's exceptional optical properties, combined with its mechanical and thermal robustness, make it an ideal material for a range of advanced optical components and high-power laser applications.1

Diamond boasts an extraordinarily broad transmission spectrum, extending from the deep ultraviolet (220 nm) through the visible light range, and into the far infrared and millimeter-wave microwave regions (exceeding 50 µm).23 This wide transparency, coupled with its naturally low absorption of light, is critical for applications where minimal signal loss and optical distortion are required. Any energy that is absorbed can be dissipated very quickly due to diamond's high thermal conductivity, ensuring the optical component is not distorted by temperature, even under intense laser irradiation.36 This makes synthetic diamond an ideal material for optical windows in high-power lasers, solid-state lasers, and gyrotrons, ensuring stable and enduring high optical quality.1

Researchers have successfully developed diamond lasers with extraordinary power ranges, producing high-energy beams that enable more precise and efficient targeting.1 This advancement is largely due to diamond's exceptional thermal conductivity and heat dissipation capabilities, which allow for the generation of hundreds of watts of power without compromising the material's integrity.1 For instance, power outputs of 400 watts have been achieved, a significant increase from just a few watts in prior years, enabling capabilities such as cutting through steel.1 Applications for these powerful diamond lasers include defense against missile threats, remote sensing, bioimaging, medicine, quantum science, and space debris management.1 Synthetic diamonds are also crucial in Raman lasers, offering power scaling improvements of over two orders of magnitude.1

In laser diode arrays, integrating a diamond heat spreader between the diode array and the submount is a significant advancement. This effectively dissipates heat from localized emitter hotspots, which is crucial for devices that often generate hundreds of watts and consist of multiple closely spaced emitters on a single chip.1 This innovation not only significantly boosts beam intensity and quality by allowing for tighter emitter spacing within the arrays but also extends the lifespan of the diode arrays, revolutionizing their potential across various industrial material processing and medical procedures.1

Furthermore, synthetic diamonds are utilized in various molecular spectroscopy applications, including synthetic diamond ATR (Attenuated Total Reflectance) prisms in FTIR (Fourier-Transform Infrared) spectroscopy.1 Their durability makes them particularly suited for diagnostic systems in pharmaceuticals, food and beverage, and alternative energy sectors.36

4.3 Medical Devices and Biosensors

The biocompatibility, extreme hardness, and chemical inertness of synthetic diamonds make them highly suitable for a growing array of medical devices and biosensing applications.4

In the medical field, synthetic diamonds are utilized in various instruments and devices where precision and durability are paramount. For instance, surgical tools coated with diamond offer enhanced durability and precision, making them ideal for delicate surgical procedures such such as ophthalmic and neuro surgery.7 This ensures cleaner cuts and extended tool life, reducing the need for frequent replacement. Additionally, synthetic diamonds are employed in advanced medical imaging equipment, such as X-ray detectors, due to their high radiation hardness, which ensures reliable performance in environments exposed to ionizing radiation.23

Beyond instrumentation, diamond's exceptional biochemical properties and biocompatibility position it as an ideal material for the fabrication of biosensors.33 Boron-doped diamond (BDD) electrodes, for example, are highly suitable for biosensors due to their wide electrochemical potential window, high chemical stability, and inert surface.33 Diamond solution-gate field-effect transistors (D-SGFETs) are a notable example, leveraging hydrogen-terminated diamond surfaces for highly sensitive signal conversion and amplification in biomedical detection.33 These devices have proven capable of detecting various biomolecules, including ions, proteins, nucleic acids, urea, and glucose, significantly improving the speed and convenience of biomedical diagnostics.33 The precise modulation of carrier concentration through the electric double layer formed at the diamond surface-solution interface allows for highly accurate detection currents.33

4.4 Water Purification Technologies

Synthetic diamonds are playing an increasingly vital role in advanced water purification technologies, particularly through their electrochemical properties when doped with boron.23

Boron-doped diamond (BDD) electrodes possess a unique combination of high chemical stability, mechanical robustness, and a wide electrochemical potential window.33 These properties enable the direct and efficient formation of highly reactive hydroxyl and oxyl radicals during electro-oxidation reactions.48 These radicals are extremely effective in purifying water by breaking down persistent organic contaminants, including pharmaceutical residues and harmful "forever chemicals" like PFAS (per- and polyfluoroalkyl substances), which are notoriously difficult to degrade using conventional methods.48

A significant advantage of this diamond-based purification method is that it eliminates the need for traditional chemical disinfectants such as chlorine, thereby reducing the introduction of secondary pollutants.48 The system can be used repeatedly without losing effectiveness, offering a highly efficient and reliable approach to water treatment.23 Synthetic diamond anodes can also facilitate ozone production on a scale appropriate for homes, hotels, and hospitals, providing a more efficient and reliable disinfection method than other currently available technologies.23

This technology is already in widespread use in large-scale industrial wastewater treatment systems and is being explored for smaller-scale applications, including potable water purification.48 Furthermore, research is exploring the possibility of creating diamond layers from waste streams, such as biogas, to purify wastewater, representing an innovative approach to circular economy principles in water management.48

4.5 Energy and Nuclear Applications

Synthetic diamonds are making significant contributions to the energy sector, particularly in high-power electronics and novel nuclear applications, leveraging their extreme thermal, electrical, and radiation-resistant properties.

In high-power electronics, synthetic diamond substrates provide excellent electrical insulation, reducing the risk of electrical breakdown and enhancing the efficiency and reliability of power electronic devices, especially in electronic power distribution.1 They are ideal heat spreaders for high-voltage power devices like insulated-gate bipolar transistors (IGBTs), significantly reducing thermal resistance and effectively doubling power ratings.1 Diamond-based devices can efficiently manage current and voltage surges in the power grid, safeguarding equipment from damage. Unlike bulky silicon switches, these diamond-based counterparts can accomplish the same tasks in compact, finger-sized devices, promising significant advancements in power management technology.1

A groundbreaking application is the development of nuclear-powered batteries using synthetic diamonds. These innovative batteries encapsulate radioactive materials, such as carbon-14, within diamonds to generate electricity without moving parts, emissions, or maintenance.1 While their power output is relatively low, their exceptional lifespan (e.g., 5,730 years to reach 50% power with carbon-14) could revolutionize long-term power solutions for remote and critical applications such as pacemakers, satellites, high-altitude drones, or spacecraft.1 This innovation also offers a potential solution for nuclear waste management by extracting carbon-14 from graphite blocks, thereby reducing radioactivity and storage costs.1

Synthetic diamond-coated sensors are also employed in nuclear power plants for accurate radiation monitoring. Their exceptional resilience allows for reliable, long-term operation in extreme environments, ensuring safety and operational integrity.1

4.6 Defense and Aerospace

Synthetic diamonds have emerged as a versatile "supermaterial" for defense and aerospace applications, where components must withstand harsh operating conditions and deliver uncompromising performance.1

In advanced defense applications, synthetic diamonds are utilized in high-power radars, sophisticated communications and electronic warfare systems, and Directed Energy Weapons (DEWs).1 Their radiation resistance, superior mechanical strength, and exceptional thermal conductivity are invaluable in these demanding environments, ensuring system reliability and longevity.1

Diamond lasers, with their extraordinary power ranges, enable more precise and efficient targeting capabilities for defense against missile threats, remote sensing, and space debris management.1 The integration of diamond heat spreaders in laser diode arrays effectively dissipates heat from localized emitter hotspots, boosting beam intensity and quality and extending the lifespan of the diode arrays, which is crucial for military-grade laser systems.1

For space exploration, synthetic diamond's radiation resistance, chemically and biologically inert properties, mechanical strength, and thermal conductivity are invaluable for spacecraft components that must operate reliably in the harsh conditions of outer space. They are used in instruments aboard Mars rovers, enhancing overall safety and performance of critical missions.1

Synthetic diamond-based components are also integral to advanced radar and communication systems due to their exceptional electrical insulating properties, which ensure interference-free signal transmission and reception. They address the urgent need for electronic devices that operate at higher frequencies and deliver increased output power while maintaining energy efficiency.1

Finally, the incredible hardness and durability of synthetic diamond make it an ideal material for armor and protective coatings on military vehicles, aircraft, and personal gear, significantly enhancing overall safety and protection for personnel and assets.1

5. Market Dynamics and Future Trajectories

The global synthetic diamond market is undergoing a significant transformation, characterized by robust growth, diversification of applications, and evolving regional dynamics.

5.1 Market Size and Growth Projections

The global synthetic diamond market was estimated at USD 25.9 billion in 2024 and is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.1% from 2025 to 2034.5 Other analyses project a CAGR of greater than 7.5% during the forecast period (2025-2030), with some estimates reaching USD 37.47 billion by 2034.22 This growth is largely driven by the rising demand for synthetic diamonds in industrial uses, where they are increasingly replacing traditional materials in cutting tools, abrasives, and drilling equipment due to their superior hardness and durability.52 By 2020, synthetic diamonds reportedly accounted for nearly 85% of all industrial diamond production worldwide.52

5.2 Dominant and Emerging Market Segments

The industrial sector, particularly cutting tools and abrasives, continues to dominate the market for synthetic diamonds, accounting for 39% market share in 2024 and projected for continued growth through 2034.5 The abrasive tools market size alone was estimated at USD 50.88 billion in 2024.5

Beyond these core industrial applications, the electronics and medical sectors are experiencing rapid growth in their adoption of synthetic diamonds for heat conductors and precision instruments.5 Newer areas such as optics and aerospace are also actively exploring additional possibilities, indicating a broadening scope for market expansion.5 The demand for artificial diamonds in the semiconductor industry is particularly expected to increase with the advancement of AI, Quantum Computing, IoT, and Autonomous Vehicles.5 The semiconductor industry, valued at USD 573.4 billion in 2022, is projected to reach USD 1.3 trillion by 2029, with a staggering CAGR of 12.2%.5 This growth is significantly aided by the superior properties of lab-grown diamonds compared to older silicon semiconductors.5

In terms of product type, the rough synthetic diamond segment continues to dominate the global market, holding approximately 66% of the market share in 2024.22 This is attributed to its widespread use in construction, mining, and oil & gas sectors for applications like quarrying saws, mining drills, and various drilling tools.22 The polished synthetic diamond segment, while smaller, is experiencing remarkable growth, projected to expand at approximately 10% during 2024-2029, driven by high-tech applications in electronics and semiconductors, particularly as heat sinks.22

Regarding manufacturing processes, the Chemical Vapor Deposition (CVD) segment is experiencing rapid growth, with a projected growth rate of approximately 11% during 2024-2029.22 This is due to its flexibility, simplicity, and suitability for industrial applications, especially in producing high-quality synthetic diamonds for electronics, healthcare, and advanced electronic devices.22 The High Pressure, High Temperature (HPHT) method also continues to grow in importance for electronics and high-powered tools.5

5.3 Regional Market Analysis

The Asia-Pacific region is a global leader in the synthetic diamond market, recording an impressive revenue of USD 9 billion in 2024 and forecasted to achieve USD 14.9 billion in 2034.5 This dominance is attributed to its strong manufacturing base and considerable industrial needs, particularly in electronics, semiconductors, construction, and infrastructure development.22 China, in particular, is a critical player, being the world's largest producer of synthetic diamonds, accounting for over 90% of the global supply.53 India is emerging as the fastest-growing market in Asia-Pacific, with a projected growth rate of approximately 9% during 2024-2029, driven by its expanding electronics manufacturing sector and increasing adoption in industrial applications, supported by government initiatives.22

The United States is the second largest market for global synthetic diamonds, with revenue of USD 5.3 billion in 2024, predicted to rise to USD 9.1 billion by 2034.5 While the jewelry segment in the U.S. is expected to see steady growth, the industrial segment is projected to experience stagnation.5 However, other emerging markets in the U.S., particularly in the electronics, medical devices, and aerospace sectors, are growing rapidly, with an expected average annual growth of 15%.5 The U.S. is anticipated to remain a primary adopter of innovation in these fields with further progress in HPHT and CVD technologies.5

Europe is also a significant market, with France identified as the fastest-growing market in the region, driven by increasing adoption in aerospace, electronics, and defense applications, alongside investments in advanced manufacturing capabilities.22 Emerging markets in Latin America (e.g., Brazil, driven by mining, construction, and oil & gas) and the Middle East and Africa (e.g., GCC countries, South Africa, driven by construction, oil & gas exploration, and mining) are also beginning to explore the potential of synthetic diamonds for industrial purposes.22

5.4 Key Market Drivers

Several factors are propelling the growth of the synthetic diamond market in industrial applications:

- Technological Advancements: Continuous innovations in HPHT and CVD manufacturing processes enable the creation of larger, higher-quality synthetic diamonds with improved consistency and reduced production costs.8 Advances in CVD techniques, in particular, are aiding the booming growth of defect-free diamonds for the semiconductor and optical industries.5

- Superior Performance: The unmatched properties of synthetic diamonds—extreme hardness, thermal conductivity, and unique electrical characteristics—make them superior to traditional materials in demanding industrial applications, leading to improved precision, efficiency, and durability.1

- Cost-Effectiveness: Synthetic diamonds are generally less expensive than natural diamonds of comparable quality, often 30-50% less.9 This affordability, coupled with their high performance, makes them an attractive option for industries seeking to reduce operational costs.3

- Sustainability and Ethical Sourcing: The production of lab-grown diamonds avoids the environmental degradation (soil erosion, habitat destruction) and ethical concerns (conflict diamonds, human rights abuses) often associated with traditional diamond mining.14 This appeals to industries and consumers increasingly prioritizing sustainable and ethically sourced materials.3

- Controlled Properties and Customization: The ability to grow diamonds under controlled conditions allows manufacturers to minimize impurities and precisely tailor properties like size, shape, color, and specific characteristics (e.g., nitrogen-vacancy centers for quantum applications).10 This customization is crucial for meeting the exact requirements of specialized industrial applications.16

- Increasing Demand from High-Tech Industries: The rapid expansion of sectors like electronics, semiconductors, quantum computing, aerospace, and medical devices is creating a growing need for advanced materials with the unique properties offered by synthetic diamonds.5

6. Challenges and Limitations

Despite the significant advancements and widespread adoption of synthetic diamonds in industrial applications, the industry faces several challenges and limitations that warrant careful consideration.

6.1 Production and Economic Challenges

One notable challenge is the potential for overproduction in domestic markets, which can lead to an imbalance between supply and demand. This overcapacity has, in some instances, caused a reduction in the prices of cultured diamonds, with prices falling by more than 50% in certain segments.58 Such price declines can adversely impact manufacturers and merchants, potentially leading to financial losses and increased market competition.58 Addressing this requires strategic measures such as implementing strict regulations on quality, certification, and import quantities to stabilize the market.58

The continued reliance on imports for both lab-grown diamonds and essential manufacturing machinery and diamond seeds presents another hurdle for some producing countries.58 This dependency can create supply chain vulnerabilities and economic leakage. Governments are increasingly supporting domestic research and development to design homegrown machinery and methods, aiming to reduce this reliance on foreign imports.58

While CVD technology has many advantages, it has historically faced challenges in yielding very large diamonds (over 3.2 carats), though this limitation is more pertinent to the jewelry sector than most industrial applications.17 For some applications, the energy-intensive nature of synthetic diamond production, particularly if reliant on non-renewable energy sources, can also be a concern, raising questions about the true environmental footprint.14 Furthermore, the generation of waste materials, including gases and chemicals, during the production process necessitates proper disposal to prevent environmental damage.14

6.2 Environmental and Ethical Scrutiny

While often touted as an eco-friendly and ethically sourced alternative to natural diamonds, the production of lab-grown diamonds is not without its own environmental and ethical considerations. The manufacturing processes, especially HPHT, require significant amounts of energy, and the source of this energy is not always renewable.14 This energy consumption can contribute to carbon emissions if derived from fossil fuels. Additionally, the processes can be water-intensive, which can be a concern in water-scarce regions.14 The generation of waste materials, including gases and chemicals, during production also necessitates proper disposal to prevent environmental damage.14

Although lab-grown diamonds are free from the ethical issues associated with conflict diamonds and human rights violations in traditional mining, concerns can still arise regarding the working conditions and wages of workers in synthetic diamond production facilities, similar to any other industrial sector.14 While currently not a significant issue, the potential for lab-grown diamonds to be used to fund conflict is a possibility that cannot be entirely ignored.14

6.3 Market Perception and Competition

Consumer attitude towards lab-grown diamonds, while improving, still presents a challenge. Despite increasing awareness and acceptance of cultured diamonds as "real" diamonds, a lingering stigma can persist, with some consumers still preferring mined diamonds.14 This perception, though more prevalent in the jewelry market, can indirectly influence the broader acceptance and perceived value of synthetic diamonds in industrial contexts.

The rapid decline in polished diamond prices, driven partly by the increased supply of synthetics, has created a crisis of confidence in the natural diamond market.59 This competition, while beneficial for consumers and industrial users seeking cost-effective alternatives, impacts the traditional diamond industry's financial resilience and long-term value perception.59 The natural diamond industry's aggressive campaigns that not only emphasize their advantages but also delegitimize natural diamonds by portraying them as "conflict diamonds" and environmentally harmful, have created a challenging competitive landscape.59

Furthermore, while lab-grown diamonds are generally less expensive, some argue that they may not hold their value over time like natural diamonds, which possess a rarity factor due to finite supply.9 This aspect, while less critical for industrial consumables, can influence investment perspectives within the broader diamond market. Quality concerns have also been raised, with some lab-grown diamonds potentially exhibiting visible inclusions or structural flaws, or color variations, although advancements in production are continuously mitigating these issues.14

7. Future Research Directions and Innovations

The field of synthetic diamonds is characterized by continuous innovation, with ongoing research and development pushing the boundaries of their properties, manufacturing efficiency, and application spectrum. These future directions promise to further solidify synthetic diamonds' role as a critical advanced material.

7.1 Advancements in Synthesis Techniques

Continuous research is focused on refining both HPHT and CVD methods to achieve higher quality, larger sizes, and more precise control over diamond properties. For HPHT, efforts are directed at improving crystal quality and scalability, making it more competitive for both industrial and jewelry markets.5 For CVD, advancements are aimed at increasing growth rates and reactor seed capacity, allowing for simultaneous growth of more diamonds and accelerating production.19 The development of Microwave Plasma Chemical Vapour Deposition (MPCVD) is particularly promising for producing diamonds with high precision, leveraging microwave energy to create plasma for crystal growth.55

Novel synthesis methods are also under investigation. The Ultrasonic Cavitation-based method, for instance, uses ultrasonic waves in a carbon-rich liquid to create high pressure and temperature conditions, leading to diamond crystallization. This method is effective for producing small, high-quality diamonds.55 Laser-assisted methods are also emerging, using precisely controlled lasers to heat carbon sources and transform them into diamonds with specific shapes and sizes.55 These advancements aim to reduce energy consumption and production costs, making lab-grown diamonds even more accessible and sustainable.55

7.2 Novel Material Engineering

Beyond simply growing diamonds, significant research is dedicated to engineering novel diamond materials with enhanced or entirely new functionalities. This includes the development of nano-polycrystalline diamonds, which are fine diamond particles tightly and directly bonded together without any inclusions in the grain boundaries.4 These materials are incredibly hard on all surfaces and lack the cleavage planes of single-crystal diamonds, making them exceptionally durable. Sumitomo Electric, for instance, spent over 20 years developing nano-polycrystalline diamonds that outperform single-crystal diamonds, revolutionizing mold manufacturing with tools that do not wear away, enabling higher accuracy and faster production.4

Research is also focused on creating specialized diamond structures and doping strategies to optimize properties for specific applications. This includes developing ultra-wide bandgap semiconductors that can operate at much higher temperatures and voltages than traditional materials, underpinning a multibillion-dollar market in advanced electronics.22 The precise control over impurity levels, such as nitrogen-vacancy centers for quantum applications or boron doping for conductivity, allows for the creation of diamonds with tailored electrical, thermal, and optical characteristics.19

7.3 Expanding Application Horizons

The continuous innovation in synthetic diamond technology is opening doors to entirely new application horizons.

- Additive Manufacturing: Synthetic diamonds are being explored for use in additive manufacturing, potentially enabling the 3D printing of diamond components with complex geometries and enhanced properties.22

- Orthopedic Medical Devices: Beyond surgical tools, research is investigating the use of synthetic diamonds as biocompatible materials for producing artificial joints and teeth, leveraging their wear resistance and inertness for long-term implants.4

- Advanced Photonics: Synthetic diamonds are being explored for use in advanced photonics, where they can be used to create components for quantum optics and nonlinear optical devices. These technologies have the potential to revolutionize fields such as telecommunications, data storage, and sensing.60

- Flexible Wearables: Their superior heat-dissipation properties enable the development of flexible and transparent wearable technology, preventing devices from overheating and ensuring more powerful, durable, and long-lasting wearable devices.1

- Nuclear Fusion: While not explicitly detailed, the mention of "Nuclear fusion applications" in a review of diamond film applications suggests potential future roles in extreme energy research.21

These ongoing research efforts, coupled with a growing emphasis on sustainable production practices and environmental certifications, indicate a dynamic future for synthetic diamonds, driven by proprietary technologies and expanding application portfolios.22

8. Conclusion and Strategic Outlook

The journey of synthetic diamonds from laboratory curiosities to indispensable industrial materials marks a profound technological revolution. Chemically and physically identical to their natural counterparts, these engineered diamonds are distinguished by their capacity for tailored property optimization, a critical advantage that surpasses the inherent variability of mined stones. This ability to precisely control characteristics like purity, hardness, thermal conductivity, and electrical properties allows synthetic diamonds to be purpose-built for demanding, high-performance applications across a multitude of sectors. This represents a fundamental shift from mere replication to true material mastery, enabling solutions that were previously unachievable or economically unfeasible.

The industrial sector currently dominates the synthetic diamond market, with abrasives and cutting tools leading the way, a testament to diamond's unparalleled hardness and wear resistance. However, the most significant growth trajectory is observed in advanced technological fields. Synthetic diamonds are becoming foundational to next-generation electronics, serving as highly efficient heat sinks that mitigate the critical challenge of thermal management in increasingly miniaturized and powerful devices. Their unique electrical properties are paving the way for ultra-wide bandgap semiconductors, promising revolutionary advancements in power electronics for electric vehicles, renewable energy systems, and 5G networks, offering unprecedented efficiency and power handling capabilities compared to silicon.

Beyond these core applications, synthetic diamonds are enabling breakthroughs in specialized domains. In quantum computing, nitrogen-vacancy centers within diamond lattices offer stable qubits for quantum information processing and highly sensitive sensing. Their broad optical transparency and thermal robustness make them ideal for high-power lasers and advanced optical components, crucial for defense, aerospace, and scientific research. In the medical field, their biocompatibility and precision are transforming surgical tools and biosensing technologies. Furthermore, their electrochemical properties are being harnessed for advanced water purification, including the destruction of persistent "forever chemicals," and even for novel nuclear battery designs offering long-duration power solutions.

The market for synthetic diamonds is characterized by robust growth, particularly in the Asia-Pacific region driven by strong manufacturing bases and increasing demand from high-tech industries. While challenges related to market perception, overproduction, and the energy footprint of manufacturing persist, ongoing research and development are actively addressing these limitations. Innovations in synthesis techniques, such as advanced CVD methods and the development of nano-polycrystalline diamonds, promise to further enhance quality, reduce costs, and expand the material's versatility.

Strategically, the future of synthetic diamonds lies in their continued evolution as a customizable, high-performance material. Industries that prioritize precision, efficiency, durability, and the ability to operate in extreme environments will increasingly turn to synthetic diamonds as an enabling technology. Investment in research and development, particularly in areas like quantum materials, advanced semiconductor design, and novel surface engineering, will be critical to unlocking the full potential of this supermaterial. As global demand for high-performance, sustainable, and ethically sourced materials continues to rise, synthetic diamonds are poised to play an increasingly pivotal role in shaping the technological landscape of the 21st century.

Works cited

- The Synthetic Diamond Revolution: Transforming Industries Across the Spectrum, accessed June 20, 2025, https://idstch.com/technology/materials/the-synthetic-diamond-revolution-transforming-industries-across-the-spectrum/

- Synthetic diamond | Definition, Techniques, & Facts - Britannica, accessed June 20, 2025, https://www.britannica.com/science/synthetic-diamond

- Applications of Synthetic Diamond in Industrial Cutting and Drilling, accessed June 20, 2025, https://www.coherentmarketinsights.com/blog/applications-of-synthetic-diamond-in-industrial-cutting-and-drilling-1509

- "Synthetic Diamonds Strengthen Our Future | Articles | Sumitomo Electric Industries, Ltd.", accessed June 20, 2025, https://sumitomoelectric.com/articles/nano-polycrystalline-diamonds-for-cutting-tools-in-manufacturing

- Synthetic Diamond Market Size, Share, Trends & Forecasts 2034, accessed June 20, 2025, https://www.gminsights.com/industry-analysis/synthetic-diamond-market

- Manufacturing Lab-Grown Diamonds - Vision Engineering, accessed June 20, 2025, https://www.visioneng.com/resources/application/lab-grown-diamond-manufacture/

- Synthetic Diamond in Moga - Dealers, Manufacturers & Suppliers -Justdial, accessed June 20, 2025, https://www.justdial.com/jdmart/Moga/Synthetic-Diamond/jdm-1104417-ent-11-3256315

- Navigating Synthetic Diamond Manufacturing Process: The Rise of a Billion-Dollar Industry, accessed June 20, 2025, https://bisresearch.com/insights/navigating-synthetic-diamond-manufacturing-process-the-rise-of-a-billion-dollar-industry

- Natural vs. Lab Created Diamond Rings - What Do the Experts Say?, accessed June 20, 2025, https://www.nathanalanjewelers.com/lab-diamonds-vs-natural-diamonds

- Comparing Lab Grown and Natural Diamond Properties - Van Drake Jewelers, accessed June 20, 2025, https://vandrakejewelers.com/blogs/jewelry-blogs/lab-grown-diamonds-comparing-physical-and-chemical-properties-with-natural-diamonds

- What is the CVD Process to Grow Lab Diamonds? - With Clarity, accessed June 20, 2025, https://www.withclarity.com/blogs/diamond/what-is-the-cvd-process-to-grow-lab-diamonds

- Natural Diamonds vs Synthetic Diamonds: Two Brilliant but Different Worlds - Celinni, accessed June 20, 2025, https://www.celinni.com/en/blog/natural-diamonds-vs-synthetic-diamonds-two-brilliant-but-different-worlds-n307

- Natural Versus Synthetic Diamonds: Fact Sheet for Members of the American Gem Society, accessed June 20, 2025, https://members.americangemsociety.org/page/naturalvslaboratorygrown

- What Are The Disadvantages of Lab Grown Diamonds?, accessed June 20, 2025, https://lioridiamonds.com/blogs/news/what-are-the-disadvantages-of-lab-grown-diamonds

- Why Synthetic Diamonds Are Worth a Look - Norton Abrasives, accessed June 20, 2025, https://www.nortonabrasives.com/en-us/resources/expertise/why-synthetic-diamonds-are-worth-look

- 10 Incredible Benefits of Lab-Grown Diamonds You Should Know - VARNIYA, accessed June 20, 2025, https://varniya.com/blogs/labgrown-diamond-news/10-incredible-benefits-of-lab-grown-diamonds-you-should-know

- Producing Lab-Grown Diamonds with Chemical Vapor Deposition ..., accessed June 20, 2025, https://www.alicat.com/articles/chemical-vapor-deposition-lab-grown-diamonds/

- What is the HPHT Process to Grow Lab Diamonds? - With Clarity, accessed June 20, 2025, https://www.withclarity.com/blogs/diamond/what-is-the-hpht-process-to-grow-lab-diamonds

- CVD Diamonds: Everything you need to know | Grown Diamond ..., accessed June 20, 2025, https://www.growndiamondcorp.com/blog/cvd-diamonds-everything-you-need-to-know/

- HPHT Diamond: High Pressure High Temperature Lab Process - Fine Grown Diamonds, accessed June 20, 2025, https://finegrowndiamonds.com/blog/hpht-diamond-everything-need-to-know

- Full article: Applications of diamond films: a review, accessed June 20, 2025, https://www.tandfonline.com/doi/full/10.1080/26941112.2024.2410160

- Synthetic Diamond Market - Production, Size & Forecast - Mordor Intelligence, accessed June 20, 2025, https://www.mordorintelligence.com/industry-reports/synthetic-diamond-market

- Synthetic Diamond Benefits and Applications - AZoM, accessed June 20, 2025, https://www.azom.com/article.aspx?ArticleID=8494

- Innovations in Electronics Enabled by Synthetic Diamond, accessed June 20, 2025, https://www.powerelectronicsnews.com/innovations-in-electronics-enabled-by-synthetic-diamond/

- OPTICAL PROPERTIES OF DIAMOND - Johns Hopkins University Applied Physics Laboratory, accessed June 20, 2025, https://secwww.jhuapl.edu/techdigest/content/techdigest/pdf/V14-N01/14-01-Thomas.pdf

- What Are Diamond Grinding Wheels: Types, Uses & Benefits, accessed June 20, 2025, https://zydiamondtools.com/what-are-diamond-grinding-wheels-and-why-should-you-care/

- A review of thermal properties of CVD diamond films - ResearchGate, accessed June 20, 2025, https://www.researchgate.net/publication/368281408_A_review_of_thermal_properties_of_CVD_diamond_films

- Getting Higher Performance from Semiconductors Using Diamonds - AZoM, accessed June 20, 2025, https://www.azom.com/article.aspx?ArticleID=21982

- Polycrystalline CVD Diamond Windows - Thorlabs, accessed June 20, 2025, https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=15962

- Applications of Synthetic Diamond-Henan Huanghe Whirlwind Co.,Ltd, accessed June 20, 2025, https://www.huanghewhirlwind.com/Applications-of-Synthetic-Diamond.html

- How Synthetic Diamond is Revolutionizing the Electronics Industry, accessed June 20, 2025, https://www.coherentmarketinsights.com/blog/how-synthetic-diamond-is-revolutionizing-the-electronics-industry-1552

- Diamond semiconductor: the ultimate semiconductor that will change the future, accessed June 20, 2025, https://en-33915.site-translation.com/media/media_detail.php?b_id=29

- Diamond FET Biosensor Fabrication and Application - MDPI, accessed June 20, 2025, https://www.mdpi.com/2079-9292/13/19/3881

- Synthetic diamond semiconductors: Smaller, faster, cooler - Electronics360 - GlobalSpec, accessed June 20, 2025, https://electronics360.globalspec.com/article/21929/synthetic-diamond-semiconductors-smaller-faster-cooler

- Future Applications of Synthetic Diamonds: Beyond Jewelry to Electronics and Medical Devices, accessed June 20, 2025, https://www.diamondguidance.com/education/market/future-applications-of-synthetic-diamonds-beyond-jewelry-to-electronics-and-medical-devices/

- Diamond lights | Electro Optics, accessed June 20, 2025, https://www.electrooptics.com/feature/diamond-lights

- www.azom.com, accessed June 20, 2025, https://www.azom.com/article.aspx?ArticleID=8494#:~:text=Electrochemical%20properties%20%2D%20Synthetic%20diamonds%20are,that%20would%20destroy%20minor%20materials.

- What is Polycrystalline Diamond (PCD) Tooling?, accessed June 20, 2025, https://gdptooling.com/what-is-polycrystalline-diamond-pcd-tooling/

- What is the main advantage of PDC bits? - Knowledge - leanoms, accessed June 20, 2025, https://www.leanomsdrill.com/info/what-is-the-main-advantage-of-pdc-bits-95257376.html

- What Are the Benefits of Diamond Sawing and Drilling - Cobra Concrete, accessed June 20, 2025, https://www.cobraconcrete.com/benefits-diamond-sawing-drilling

- Choosing the Right Diamond Grinding Wheel: Types and Applications, accessed June 20, 2025, https://info.eaglesuperabrasives.com/blog/choosing-the-right-diamond-grinding-wheel-types-and-applications

- Diamond Polishing Compound: Precision Tool for Engineering - Grish, accessed June 20, 2025, https://grish.com/diamond-polishing-in-precision-engineering/

- Diamond Compound Paste - Polishing and Lapping - Hyperion Materials & Technologies, accessed June 20, 2025, https://www.hyperionmt.com/en/products/Compound-Slurries/diamond-compound-paste/

- Introducing Quantum Diamonds: Enabling the Next Generation of Quantum Technologies - ACS Material, accessed June 20, 2025, https://www.acsmaterial.com/blog-detail/introducing-quantum-diamonds-enabling-the-next-generation-of-quantum-technologies.html

- - Diamond Spin - At the Forefront of Quantum Computer Hardware Research | Fujitsu Global, accessed June 20, 2025, https://global.fujitsu/en-global/technology/key-technologies/news/ta-fujitsus-diamond-spin-based-quantum-computer-20240909

- Analysis of Diamonds by FT-IR Spectroscopy - Thermo Fisher Scientific, accessed June 20, 2025, https://assets.thermofisher.com/TFS-Assets/CAD/Application-Notes/D10278~.pdf

- Natural vs. Synthetic - World Gemological Institute, accessed June 20, 2025, http://web.wgi-global.com/natural-vs-synthetic/

- Purifying water with diamonds - TU Delft, accessed June 20, 2025, https://www.tudelft.nl/en/stories/articles/purifying-water-with-diamonds

- Shaping the future with synthetic diamonds – News Stand, accessed June 20, 2025, https://www.observer24.com.na/shaping-the-future-with-synthetic-diamonds/

- The Unexpected Role of Lab-Grown Diamonds in Green Energy - Ouros Jewels, accessed June 20, 2025, https://ourosjewels.com/blogs/lab-grown-diamonds/role-of-lab-grown-diamonds-in-green-energy

- Synthetic Diamond Market Size, Share & Forecast 2034 Report, accessed June 20, 2025, https://www.marketresearchfuture.com/reports/synthetic-diamond-market-11833

- Synthetic Diamond Market Size (2024-2033) - Emergen Research, accessed June 20, 2025, https://www.emergenresearch.com/industry-report/synthetic-diamond-market/market-size

- Global Market Trends and Forecasts for Synthetic Diamonds: Growth Sectors & Emerging Markets - Diamond Guidance, accessed June 20, 2025, https://www.diamondguidance.com/education/market/global-market-trends-and-forecasts-for-synthetic-diamonds-growth-sectors-emerging-markets/

- The Future of Sparkle: Innovation and Trends in Lab Grown Diamonds - Earthly Jewels, accessed June 20, 2025, https://earthlyjewels.co/blogs/blog/the-future-of-sparkle-innovation-and-trends-in-lab-grown-diamonds

- The Future of Lab-Grown Diamonds: Technologies and Innovations - Diamondrensu, accessed June 20, 2025, https://diamondrensu.com/blogs/lab-grown-diamonds/the-future-of-lab-grown-diamonds-technologies-and-innovations

- The Benefits of Lab Grown Diamonds for Ethical Jewellery Buyers, accessed June 20, 2025, https://www.revediamonds.com/us/blog/the-benefits-of-lab-grown-diamonds-for-ethical-jewellery-buyers

- Pros and Cons of Lab-Grown Diamonds: An Impartial Analysis - Diamondrensu, accessed June 20, 2025, https://diamondrensu.com/blogs/lab-grown-diamonds/pros-and-cons-of-lab-grown-diamonds

- Challenges in The Lab Grown Diamond Industry, accessed June 20, 2025, https://www.growndiamondcorp.com/blog/challenges-in-the-lab-grown-diamond-industry/

- The 2024 Diamond Crisis: An Industry at Its Breaking Point - Rapaport, accessed June 20, 2025, https://rapaport.com/magazine-article/the-2024-diamond-crisis-an-industry-at-its-breaking-point/